About us

Technical head start with more than 90 years of experience

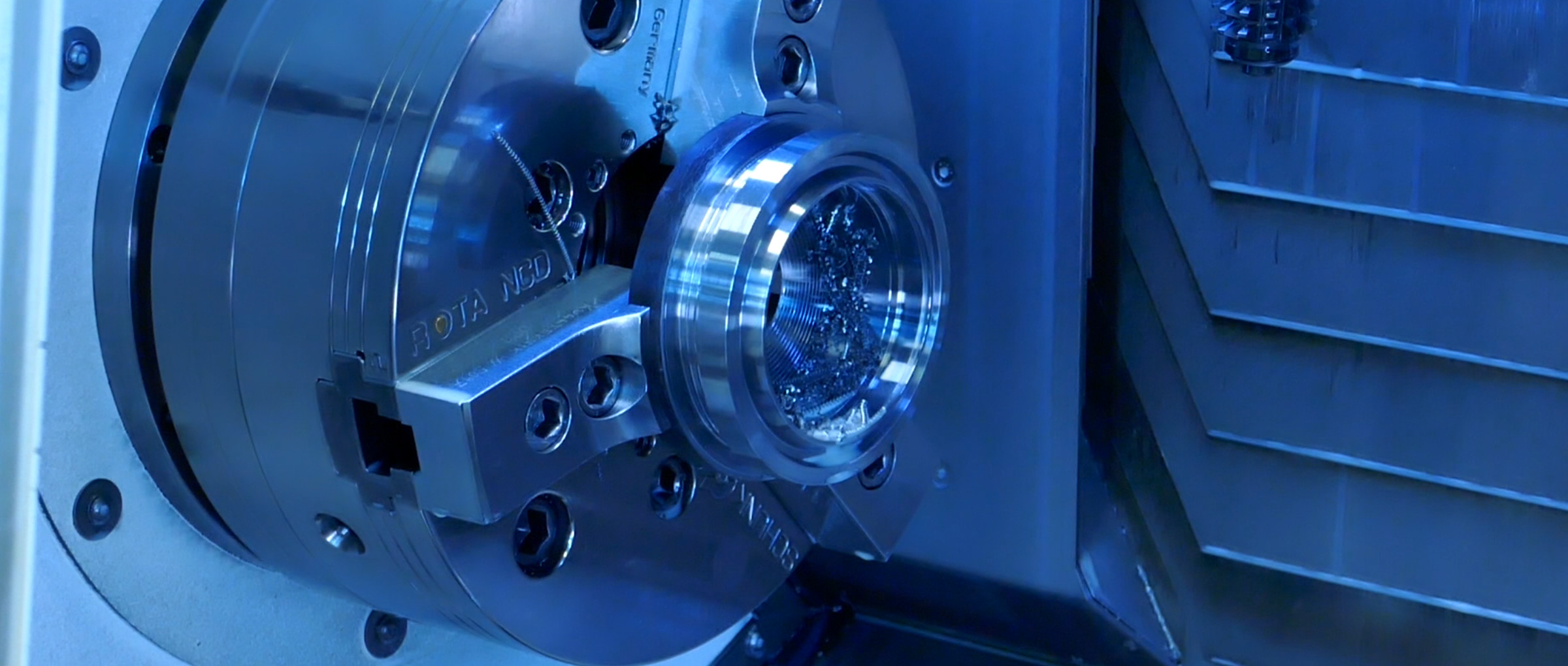

We are characterised by supplying the things that others cannot, offering everything from fine mechanical components measuring just millimetres up to machine shafts of several metres in length.

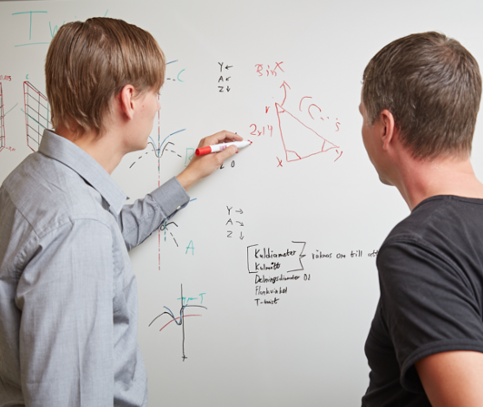

However, the most important aspect is not what we produce, but rather how we produce it.

At a time when developments are moving so quickly that we will be producing something completely different within a few years, it is the road to the finished product that is the important thing. Our desire is to develop alongside new technology and to adapt it to fit our particular segment. The way we solve this task always stems from our expertise, methods and the experience we have amassed over more than 90 years. All with the aim of ensuring that, as our customer, you can supply your own world-leading products without ever compromising on quality.

This is what we refer to as Mikro-quality